Adhesive bonding is one the key factors to ensure that future railway vehicles will be lighter

Adhesively bonded joints can join dissimilar materials whilst being reliable, efficient, robust, and reparable

Adhesively bonded joints can join dissimilar materials whilst being reliable, efficient, robust, and reparable

|

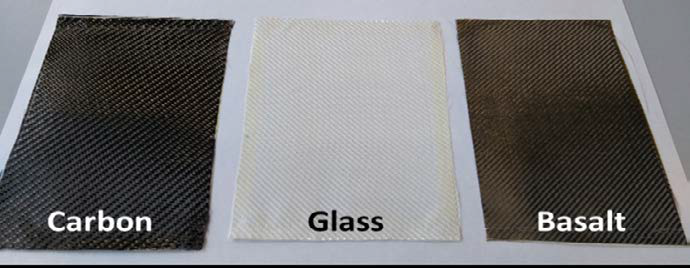

The development of new lightweight materials such as fibre reinforced plastics, which cannot be welded, along with the combination of dissimilar materials (e.g. aluminum-composites), require the determination of suitable joining methods. Adhesive bonding technology has the capability of joining dissimilar materials, as well as unique characteristics such as lower manufacturing costs, damage tolerance, design flexibility, enhanced fatigue endurance and load transfer efficiency

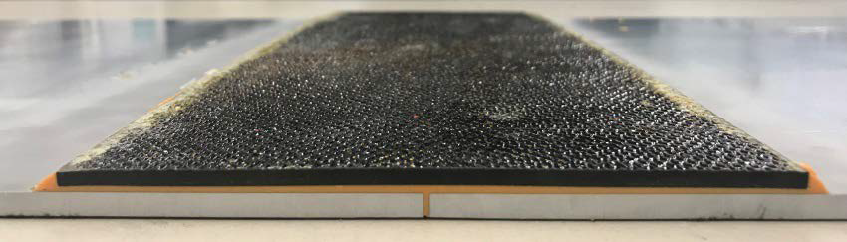

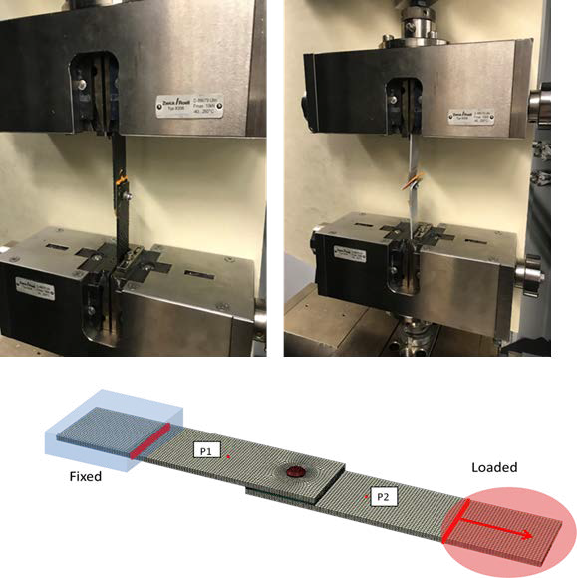

In the Mat4Rail project, two classes of adhesives were investigated aiming to cover both primary and secondary structures of railway vehicles: structural adhesives (applied for primary structures) and elastic adhesives (applied for secondary structures). Joining concepts were developed including aspects such as the selection of adhesives, joint design, surface preparation, manufacturing, automation, quality assurance, and multi-material joining. Due to the requirements of repair, maintenance, refitting and recyclability, solutions to obtain dismountable adhesive joints were analysed. These solutions include the combination of adhesive bonding with mechanical fastening (i.e. hybrid joining) aiming to profit from the benefits of both joining methods.

|

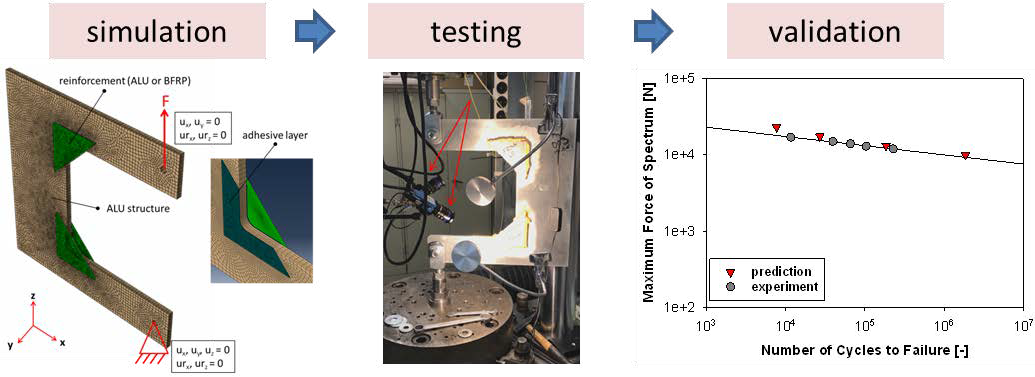

The static and fatigue strength assessment is very important for the design and safety of railway structures since it can provide a direct relationship between materials’ mechanical properties, the loads being applied and the geometry of the component. In the Mat4Rail project adhesive joints were used as an example to propose how to extend the homologation procedures with respect to the physics of deformation and damage accumulation in polymeric materials. By addressing the limitations of current methods, the fatigue assessment approach proposed by Mat4Rail will be able to validate and homologate the new materials which will constitute the next generation of the carbodies.

A component-like homologation sample was constructed based on the corners of the windows of a railway vehicle. The final validation of the operational strength was carried out by fatigue testing the component-like homologation sample under variable amplitude load spectrum. Predictions were in very good agreement with experimental results evidencing the effectiveness of the fatigue assessment approach.

A component-like homologation sample was constructed based on the corners of the windows of a railway vehicle. The final validation of the operational strength was carried out by fatigue testing the component-like homologation sample under variable amplitude load spectrum. Predictions were in very good agreement with experimental results evidencing the effectiveness of the fatigue assessment approach.

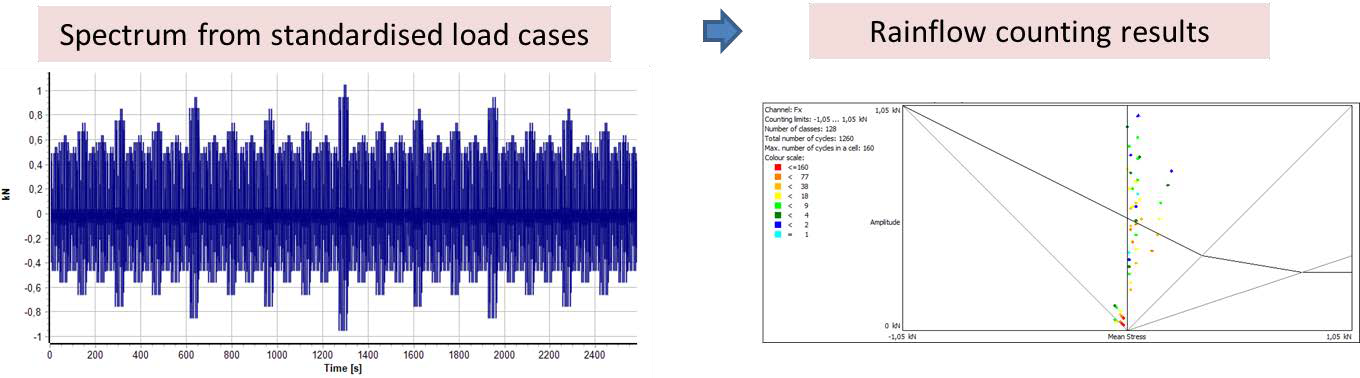

The load spectrum was defined based on a method developed within Mat4Rail, which allows the determination of homologation load spectra from standardised load cases. The analysis of the spectrum was carried out using Rain flow Counting techniques.

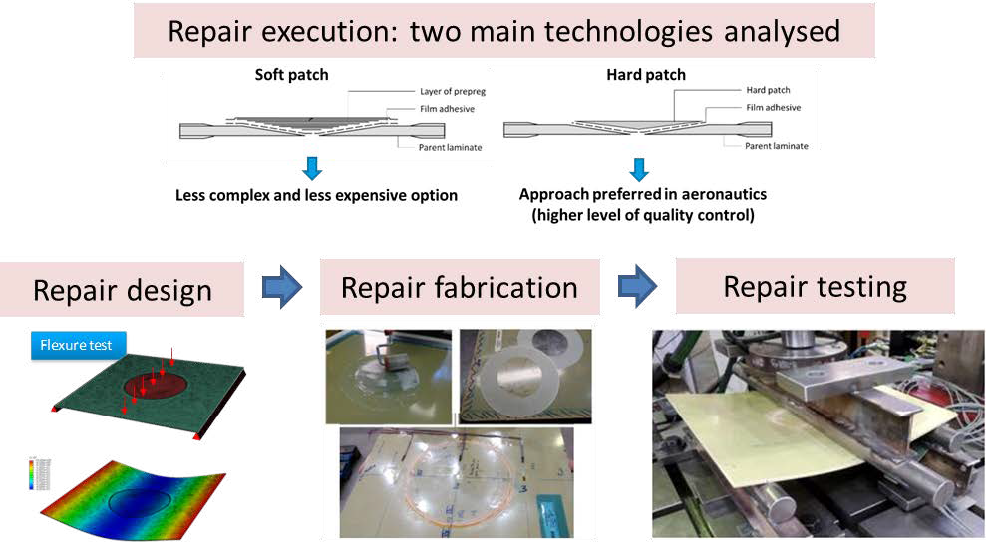

Maintenance and reparability constitute a key aspect when introducing new material technologies in transport systems. All vehicles require regular inspections with established procedures to ensure structural integrity, efficiency and safety during their service life. In addition, repair strategies are needed to guarantee (or in some cases to extend) the vehicles life.

The work done in Mat4Rail about repair technologies covered these aspects proposing two main repair technologies: soft patch and hard patch. These technologies were validated in terms of design, fabrication and testing ensuring the effectiveness of the proposed solutions.