|

Novel EN-45545 compliant composites validated in Mat4Rail project

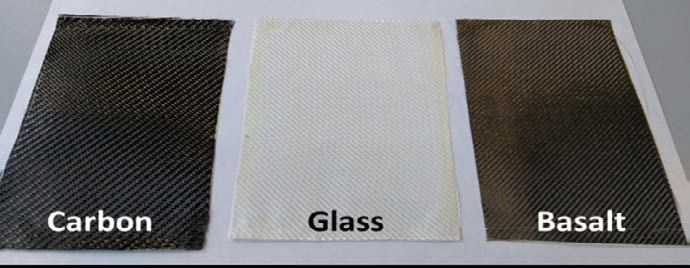

The composites are based on novel epoxy, benzoxazine and hybrid chemistry resins with improved fire resistance developed in the framework of the project Six novel fibre reinforced composites have been characterised and validated to Fire, Smoke and Toxicity (FST) performance according to EN45545-2 standard and mechanical properties (including fatigue). Within the development of these six composites, three different types of fibre reinforcements (carbon, basalt and glass) and three different types of novel resins have been characterized to evaluate and compare the potential of these six raw materials for their application in the manufacturing of carbody parts. Five composites achieved HL2 classification for R7, R8 and R17 carbody external applications. Read More |

|

Adhesive bonding is one the key factors to ensure that future railway vehicles will be lighter

Adhesively bonded joints can join dissimilar materials whilst being reliable, efficient, robust, and reparable The development of new lightweight materials such as fibre reinforced plastics, which cannot be welded, along with the combination of dissimilar materials (e.g. aluminum-composites), require the determination of suitable joining methods. Adhesive bonding technology has the capability of joining dissimilar materials, as well as unique characteristics such as lower manufacturing costs, damage tolerance, design flexibility, enhanced fatigue endurance and load transfer efficiency. Mat4Rail developed methods for the design, strength assessment, testing, refitting, maintenance and repair of adhesively bonded joints for railway structures. Read More |

|

Three future solutions for innovative train access door systems

Railway door technology in motion The search for new materials for access door systems (i.e. composites, metallic alloys) and their integration techniques (“one-shot” injection, welding & adhesive processes etc.) were addressed as part of the WP5 Innovative Access Door Systems, through innovative approaches considering relevant criteria, such as production costs, manufacturing aspects and railway constraints. Read More |

|

Virtual train prototype successfully finalised and presented in Paris

Great feedback from railway industry leaders at the final Mat4Rail event in Paris for the development of the virtual train prototype showing the Innovative Driver’s Cabin and the Innovative Plug & Play System The innovative design developments of SPIRIT and NVGTR were combined and presented in a versatile virtual prototype train model to showcase Mat4Rail’s visionary interior design developments. A neutral train model was developed in coordination with PIVOT, which is a hybrid between a commuter train and an inter-regional train. It consists of two carriages, each having a driver cabin at the end/front. To give it a realistic and appealing design, several train interior elements and modules were designed. Read More |

|

Final project event with live Mat4Rail demonstrators held in Paris

In joint collaboration with the Shift2Rail Joint Undertaking projects PIVOT, Mat4Rail, RUN2Rail and FAIR Stations on 17th September 2019 After two exciting years of Mat4Rail the final project event was held in collaboration between the Shift2Rail Joint Undertaking project’s PIVOT, Mat4Rail, RUN2Rail and FAIR Stations in Paris, France on the 17th September 2019. All four projects presented their developments and main results performed within the Shift2Rail Innovation Programme 1 (IP1) “Cost-efficient and reliable trains, including high-capacity trains and high-speed trains”. Read More |